(803)609-7630

Paving Company

in Columbia, SC

Concrete & Asphalt Paving Contractors serving the Midlands area of South Carolina!

What's the process?

Request Free Estimate

Receive your free estimate in 3 easy steps:

1) Click the "GET FREE ESTIMATE" button.

2) Pick a date that works for you.

3) Fill out our short contact info form.

AND DONE! Our experts will be in contact with you shortly to verify the meeting!

Review, Verify, & Accept Your Quote

After you have received your estimate and verified with our experts that it is everything you want...

IT'S TIME TO CELEBRATE! You're on the way to saving money now and every other year our high-quality paving work last without needing costly repairs!

Have Piece of Mind Every Step of the Way & Years After!

Our experts will verify you love the project every step of the way AND are actually getting what you've paid for.

Affordable Asphalt Co. offers an attention to detail and commitment to quality that allows us to offer a free 1-year warranty on all work!

Ready to get started?

OUR SERVICES

ASPHALT SERVICES

Asphalt Paving

Asphalt Resurfacing/Overlay

Recycled Asphalt Paving

Sealcoating

Pothole Repair & Crack Filling

CONCRETE SERVICES

Paving (Driveways, Sidewalks, Patios, & Stairs)

Crack Repair

Concrete Patching

Stamped Concrete

MAINTENANCE SERVICES

Line Striping

Base Grading

Crack Filling

Pressure Washing

Aggregate Delivery

OUR WORK

Who is Affordable Asphalt Co.?

Affordable Asphalt Co. is one of the most trusted asphalt paving companies that has been serving South Carolina since 2019. With decades of combined experience, we have learned communication with the customer is key! Hire our team today and experience satisfaction every step of the way and years after with our premiere customer verification system that allows you to be assured every step of the way.

2

LOCATIONS

35

TEAM MEMBERS

2945

PROJECTS

754

SATISFIED CLIENTS

Need more info?

Frequently Asked Questions

Learn from the experienced South Carolina Paving Contractors at Affordable Asphalt!

Question 1. How do I find reliable paving companies near me?

To find trusted paving companies near you, look for licensed and insured contractors with strong local reviews, clear estimates, and experience in both residential and commercial paving. At Affordable Asphalt Co., we proudly serve the South Carolina area with dependable, affordable paving services.

Question 2. What services do concrete driveway companies near me typically offer?

Concrete driveway companies near you generally offer new driveway installation, resurfacing, repair, and sealing. Affordable Asphalt Co. partners with top local concrete driveway contractors to ensure lasting quality.

Question 3. Do you offer asphalt paving near me?

Yes! Affordable Asphalt Co. offers professional asphalt paving near you throughout South Carolina. We handle everything from driveways to large parking lots.

Question 4. What should I look for in asphalt companies near me?

Look for asphalt companies that offer experience, competitive pricing, and strong warranties. Affordable Asphalt Co. is one of the top-rated asphalt companies near you, known for reliable workmanship.

Question 5. What’s the difference between asphalt and concrete for driveways?

Asphalt driveways are generally more affordable and faster to install, while concrete driveways offer a longer lifespan with less maintenance. Our driveway contractors can help you decide which is right for your home or business.

Question 6. What does residential driveway paving include?

Our residential driveway paving includes site prep, grading, base installation, and final surfacing with asphalt, concrete, or pavers. We also offer maintenance services like sealcoating and crack repair.

Question 7. How do I maintain my asphalt driveway?

To maintain your driveway, sealcoat it every 2–3 years, fill cracks promptly, and avoid heavy loads. We offer asphalt sealcoating near you to keep your surface in top shape.

Question 8. Do you offer both new paving and resurfacing services?

Yes! Whether you need a brand-new installation or resurfacing of an existing surface, our team of asphalt and paving contractors near you can deliver long-lasting results.

Question 9. Why choose Affordable Asphalt Co. over other driveway companies near me?

We combine competitive pricing, high-quality materials, and local expertise. As one of the most reliable commercial & residential paving companies near you, we’re committed to excellence and customer satisfaction in every project.

Fill out the form below to get in contact with us!

I confirm that I want to receive messages from Affordable Asphalt Co. using the contact information provided.

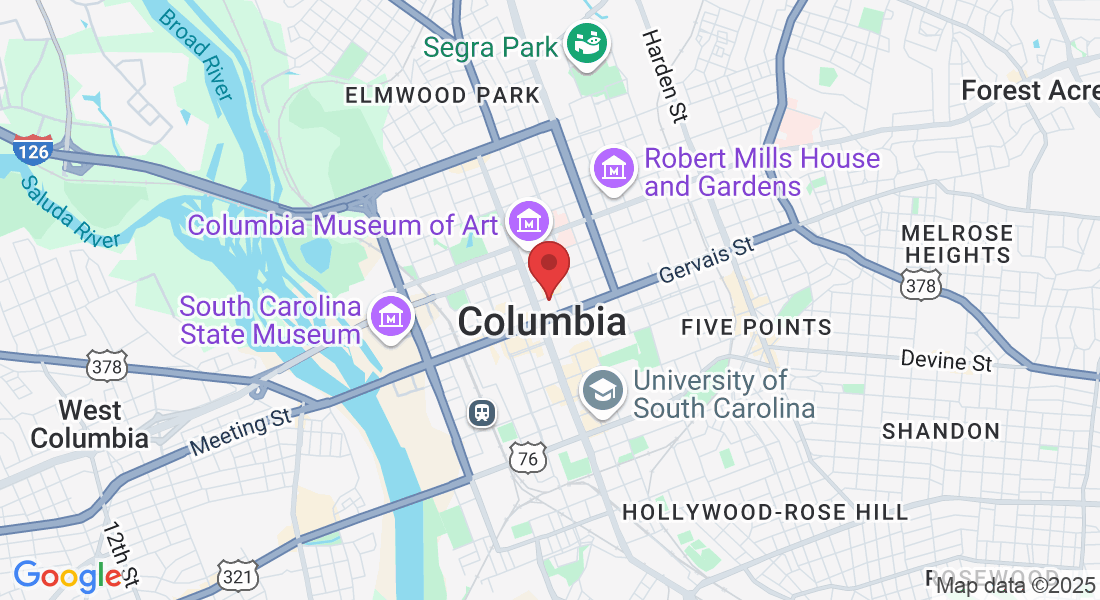

Where do we serve?

Affordable Asphalt is headquartered in Columbia, SC, and has paved all along the east coast of America for our corporate clients. Over the years of honest quality driven work, our paving contractors has grown to service all of the cities & towns in Richland County, Lexington County, Calhoun County, Fairfield County, Sumter County, Orangeburg County, Laurens County, York County, Lancaster County, Charleston County, Greenville County, Spartanburg County & more on a regular basis!

Innovation

Fresh, creative solutions.

Integrity

Honesty and transparency.

Excellence

Top-notch services.

CONTACT US

COMPANY

LEGAL

BUSINESS HOURS

Monday: 8 A.M. - 6 P.M.

Tuesday: 8 A.M. - 6 P.M. Wednesday: 8 A.M - 6 P.M.

Thursday: 8 A.M. - 6 P.M.

Friday: 8 A.M. - 6 P.M.

Saturday: 9 A.M. - 2 P.M.

Copyright 2025. Affordable Asphalt Co.. All Rights Reserved.